Puma PRODUCTS

Screw Air Compressors

Screw Air Compressors With Tank

Variable Speed Screw Compressors

Piston Type Air Compressors

Piston Air Compressors (Aluminium)

Air Dryers And Filters

Dental Air Compressors

Dental Air Compressors With Dryer

Dental Air Compressors With Cabin

Gasoline Compressors

Abac Air Pumps (Aluminum)

Compressor Air Pumps (Cast Iron)

PRODUCTS

Air Dryers And Filters

SUPPORT CENTER

Customer Support Center

.+90 342 337 85 00

Image Gallery

Technical Specs

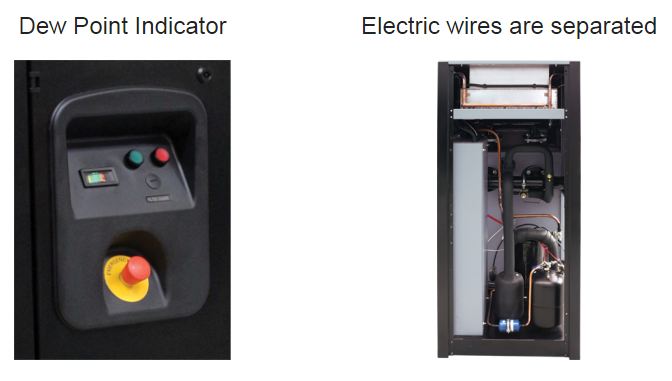

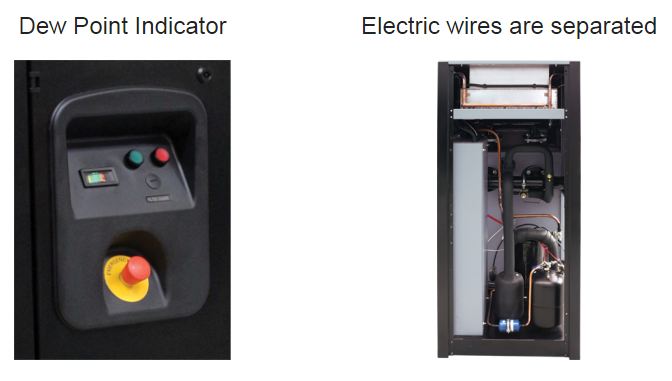

Dew point indicator is standard

Dew point indicator is standard on control panel MKE 23 – MKE 5085 and MKE 5850 up to MKE 12500 has as a standard Digital Cycling capabilities.

Electrical wires are separated from Refrigerant side

There are very few electrical wires inside the refrigerant side of the dryer. Electrical box has an external cover with access from the outside of the dryer. Therefore there is no need to open dryer panels electrical access

Compact Design

Puma dryers are highly reliable, efficient, have small space demands and offer low cost ownership. Puma Refrigerated Air Dryers are suitable for the smallest installation spaces. Having two filters integrated into the dryer frame offers a huge advantage to the service techs and end users. The integrated filters save labor time, piping cost and space at the facilities where the Puma Dryer is used. The compact size also offers flexibility and economy during their transport.,

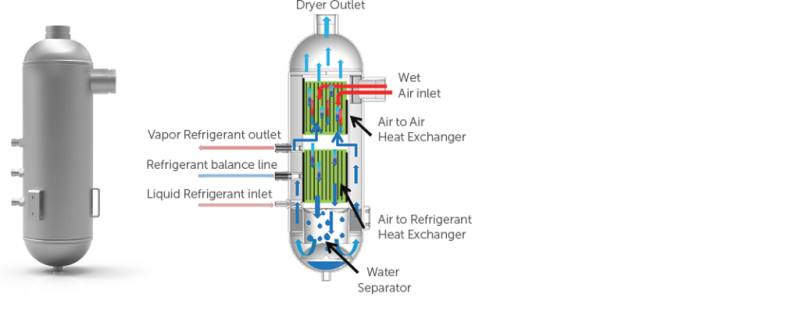

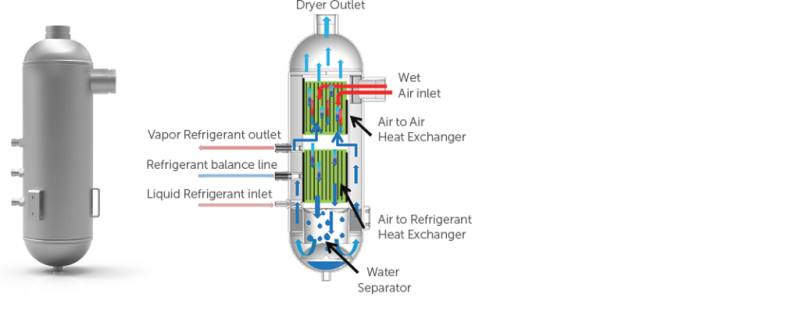

Aluminum Plate Heat Exchanger is standard

Very Low Pressure Drop

Thin Aluminum Plate Thickness

High Heat Transfer Surface Area

Strong Due to External Thick Cylindrical Wall

Water Separator is Optimized for Best Performance

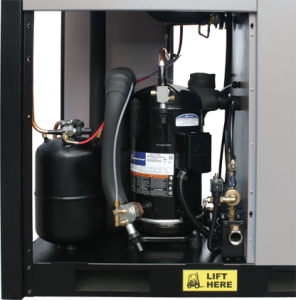

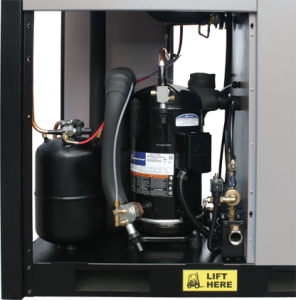

Scroll Compressors

Scroll Compressors are energy efficient and strong against liquid shocks. For energy saving scroll compressors are used for 400 Nm³/h and above MKE and MKP Dryers.

Easy Access

Easy access in to the cooling components in seconds by the help of screw free panels and plastic handless. Easy for Service and more working space. Service techs save time by not having to remove fastners.

Zero Clearance Compressed Air Filters with High Performance Elements

Compressed Air Filter kit is standard on the Puma Dryers. The filter with X Element (coalescing filter for water removal) is used for up to 1 micron particules and the Filter with Y Element (coalescing filter for oil removal) is used to remove oil down to 0.01 ppm Zero clearance design helps service technicians to replace the element in minutes. Puma Refrigeranted Air Dryers are designed by engineers who had received all of the design feedback from field engineers and service technicians. This service friendly design makes Puma dryers very unique in the industry.Dryer Filter kit which has 2 elements, 2 automatic drains and 2 viton o-rings helps the customers to operate the dryers at its best performance until next planned maintenance. Replacing drains on the filters is very critical when replacing elements. Because drains may get clogged with dirt and oil over time.

Grooved couplings and fittings

On Compressed Air lines, Grooved couplings and fittings are commonly used in the industry. These couplings increase flexibility on connections, help the service technician to dismantle and assemble pipes easily and quickly

Excessive Water Droplet Drains

Liquid water droplets coming from the line to the inlet of the dryer is seperated by the inlet filter and drained. Filter auto drain have manual valves on it. This allows the system to be depressurized when these filters go to service.

Pressure Drop Alarm Sensor

Pressure drop is a huge cocern in compressed air. In many applications high pressure drops will cause a decrease in the pressure at the point of use. Sometimes this low pressure is not enough for the machines or processes to operate correctly. In addition dirt particles and oil in the compressed air system may block the filters quickly. It is important for the end users and service technicians to recognize if there is a problem in the system. On the Puma dryers a Pressure Drop Alarm Sensor is located on the inlet filter measures the pressure drop on the inlet filter element. This creates a signal when pressure drop is higher than the set value and triggers an alarm on the front panel. When that alarm goes off the filter elements and auto drains are to be replaced.